3D printing is leaving the tech conferences and heading into our homes

Experts predicted that by 2018 we’d be 3D printing our own food, furniture and fashion from home. The revolution is yet to arrive but we can see the shape of things to come

You know that slightly niggly, slightly crazy feeling you get when you feel something or someone is watching you? I have that feeling today as I sit writing about a tech subject that’s very topical and very exciting.

The eyes have it, full of soulfulness and a sense of spiky intellect. The hair is ruby-red with snowy white bands and the ears are bobbed... the likeness is fairly uncanny as I look at Sophie, a beautifully rendered 3D sculpture of my almost decade-old Cavalier King Charles Spaniel. Her sandstone replica sits serenely, almost regally, on the corner bookshelf while the real dog lies on a cosy rug snoring soundly, oblivious to the clear advances in tech over the past few years that have made the exactness of her “clone” possible.

From 3D sculptures of our pets to fashion and huge strides forwards in medical applications, 3D printing is really starting to wow.

“The advances that the industry is making today are truly revolutionary,” explains Sophie’s creator, Lars B Andersen of Arty Lobster. “At the start of 2018, I feel that we are on the brink of a sea change in 3D printing, and much closer to turning the vision of making the digital physical than ever before.

“The tech has come on leaps and bounds just over the past several months; so much so that it’s now being used creatively to make everything from jewellery to fashion to the aerospace sphere in making jet engine parts. Perhaps most extraordinary, however, is how it’s starting to be used medically to create dentures, bones and even human organs and body parts using groundbreaking 3D bioprinting techniques.”

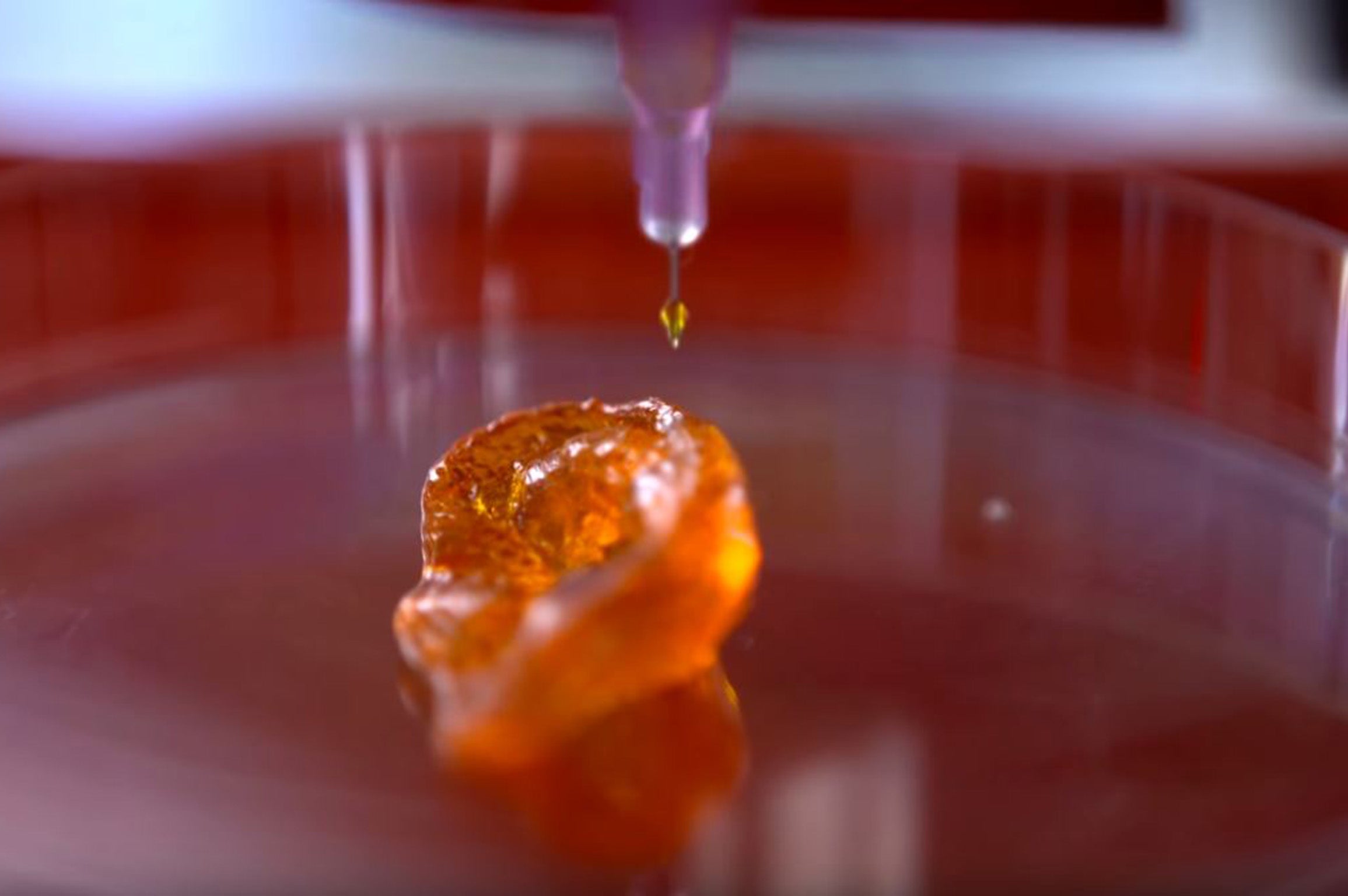

Bioprinting is a revolutionary process where layers of living cells are printed or deposited on a gel surface layer by layer and used to form three-dimensional structures such as limbs, organs and vascular systems. The so-called 3D living ink or “Flink” is still in its relative infancy.

Step forwards 50 or so years and imagine a time when experts possess the ability to bioprint a whole human being. Not a Frankenstein future, but, far, far more excitingly, a revolutionary answer to paralysis and limb replacement. In the future, there may be no need for a donor register or anti-rejection drugs as our limbs could be grown from our own stem cells in a lab. Imagine the sci-fi-like possibilities that look set to become fact.

3D printing in the medical realm is already coming on leaps and bounds.

The tragic death of a beloved son from cerebral palsy inspired one family to find a unique way of helping others touched by the condition. Samiya and Naveed Parvez set out to find a better method of producing orthoses – artificial external devices used to support the limbs or spine or otherwise assist with movement – eventually discovering the revolutionary possibilities of 3D technology to solve the problem. The couple successfully crowdfunded their medical technology company, Andiamo, named after their son, Diamo, and the Italian phrase meaning “let’s go”, and started treating patients in the UK in late 2014. Andiamo provides clinical assessments to carry out a 3D scan of a patient so that a perfectly fitting orthosis can be 3D printed. The resultant device is a 65 per cent lighter, bespoke fit for the patient, meaning far fewer hospital visits, as well as improved mobility and comfort compared to traditional plaster cast alternatives.

The World Health Organisation has estimated that 30 million people in low-income countries need prosthetic limbs. There is hope that 3D scanning and printing may be able to help.

3D advances are already achieving remarkable things. In 2014, for example, surgeons in Swansea were able to use 3D printed parts to reconstruct the face of a motorcyclist who had been seriously injured in a road accident. Last year, an American woman who had suffered from a rare bone cancer benefited from the advances when surgeons fitted her with a 3D printed sternum and rib cage.

The military is yet another area that is benefiting from the 3D printing revolution. The sector is experimenting with everything from 3D printed drones and aircraft parts to missiles. There are numerous benefits of investing in the new tech, from reduced costs to more innovative battle solutions – 3D tech could be produced in the theatre of war to fit the demands of combat. 3D printing has also hit the world of fashion, with designers now experimenting with mostly flamboyant creations designed to show off their creativity.

More practically, Nike is using 3D printing to prototype and manufacture trainers while New Balance has invested in the technology to customise running shoes for athletes. 3D scanning and printing is even bringing the past to life as museum artefacts, relics, fossils and dinosaur bones are being completed or replicated using the technology. Ancient monuments – including those under threat from extremist attacks – are being saved for posterity.

There is mounting evidence that the home market is ripe for exponential growth too. Gartner Research, a global IT research firm, estimates that sales of cheaper printers in the sub-£700 range – an important driver of the market – will account for 28.1 per cent of sales by close of 2018, up from 11.6 per cent in 2014.

Exciting and hugely innovative 3D printing technology is starting to embrace all industries. In future, there’s a distinct chance that we’ll be 3D printing our own furniture, clothes and even food. The question is: will the home market remain niche while industry ploughs time and money into legions of seemingly sci-fi-like innovations? Only time will tell. For now, I’ll content myself with admiring the beauty of my little 3D pet sculpture gazing back at me from the bookshelf.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments

Bookmark popover

Removed from bookmarks