ISS astronauts use 3D printer to create wrench after Nasa emails design specifications

Nasa hopes this is another step towards making astronauts and space missions more self-reliant

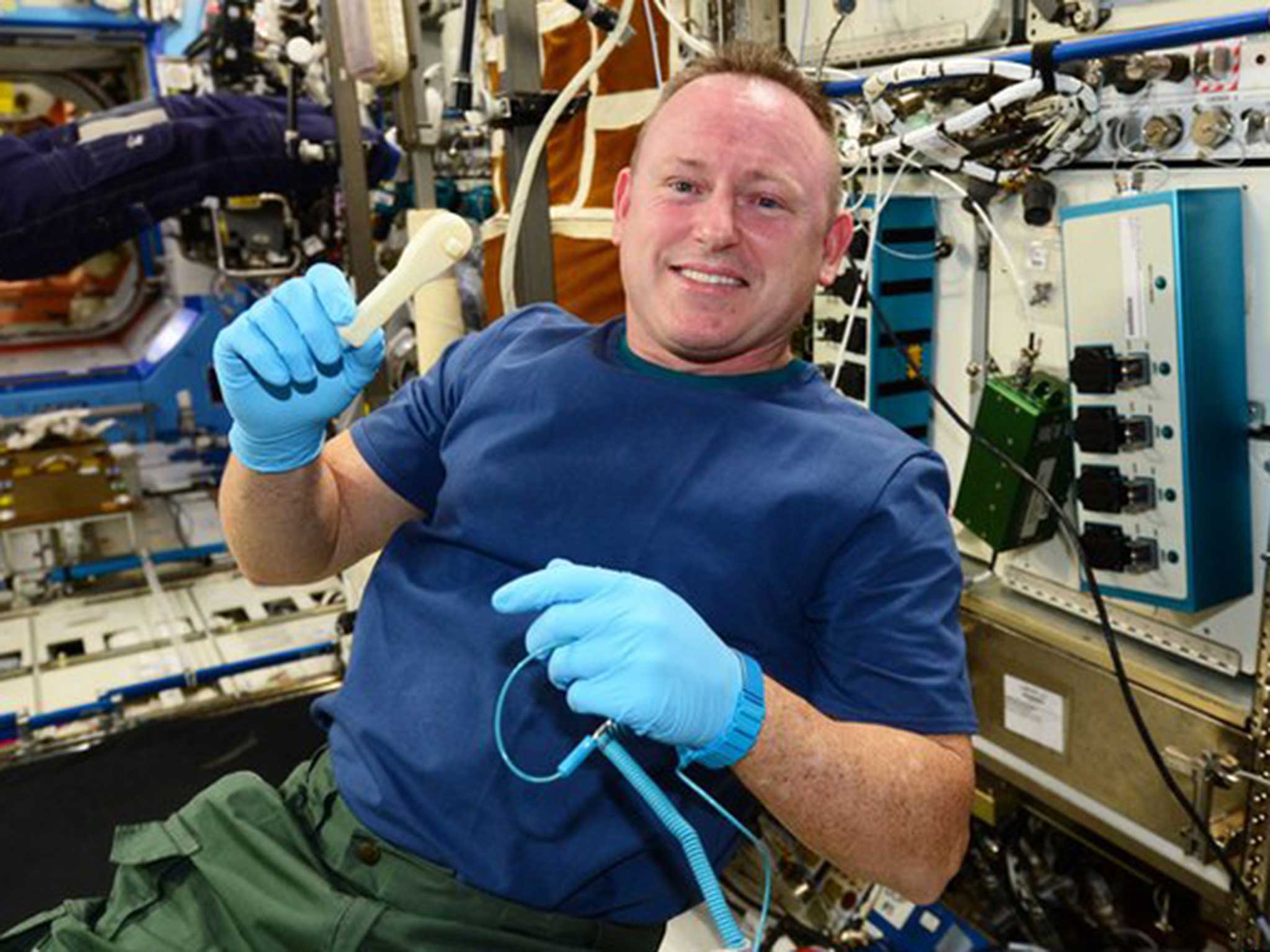

Astronauts on the International Space Station have used a 3D printer to create a new wrench, after Nasa emailed them instructions.

It is believed to be the first time Nasa has “emailed” an object to space. Previously, the space programme would take months flying a needed object up with the next mission.

The problem arose when International Space Station (ISS) commander Barry Wilmore mentioned on the radio he needed a ratcheting socket wrench.

He was overheard by a Californian company, Made In Space, who designed the 3D printer on board the space station. The printer was sent up two months ago – and first created a replacement part for itself.

Founder of Made In Space Mike Chen told the BBC: "We had overheard ISS Commander Barry Wilmore (who goes by "Butch") mention over the radio that he needed one, so we designed one in CAD and sent it up to him faster than a rocket ever could have."

Although this is not the first object made in space (there have been 21) it is another important step forward allowing astronauts to be increasingly self-sufficient.

The 20-odd objects created so far will be returned to earth and examined.

"We will use them to characterise the effects of long-term microgravity on our 3D-printing process, so that we can model and predict the performance of objects that we manufacture in space in the future,” Mr Chen told Wired.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments

Bookmark popover

Removed from bookmarks