Researchers able to make better artificial eyes using 3D printing – study

The eyes produced may have a more natural appearance and a better fit, compared to current methods, experts said.

Researchers have developed a faster and easier way of 3D printing more realistic custom artificial eyes.

The eyes produced may have a more natural appearance and a better fit, compared to current methods, the scientists suggest.

Experts say that about eight million people around the world wear a prosthetic eye, and rehabilitation can be important for psychological acceptance and physical appearance.

However, the current manufacture process of custom eyes is time-consuming and requires highly skilled manual labour to handcraft each prosthesis for an individual patient.

This process can take more than eight hours of work and produces artificial eyes of varying quality, according to the researchers.

Johann Reinhard, from Fraunhofer Institute for Computer Graphics Research IGD, in Germany, and colleagues developed and tested a digital process to produce the prostheses for patients who need an artificial eye.

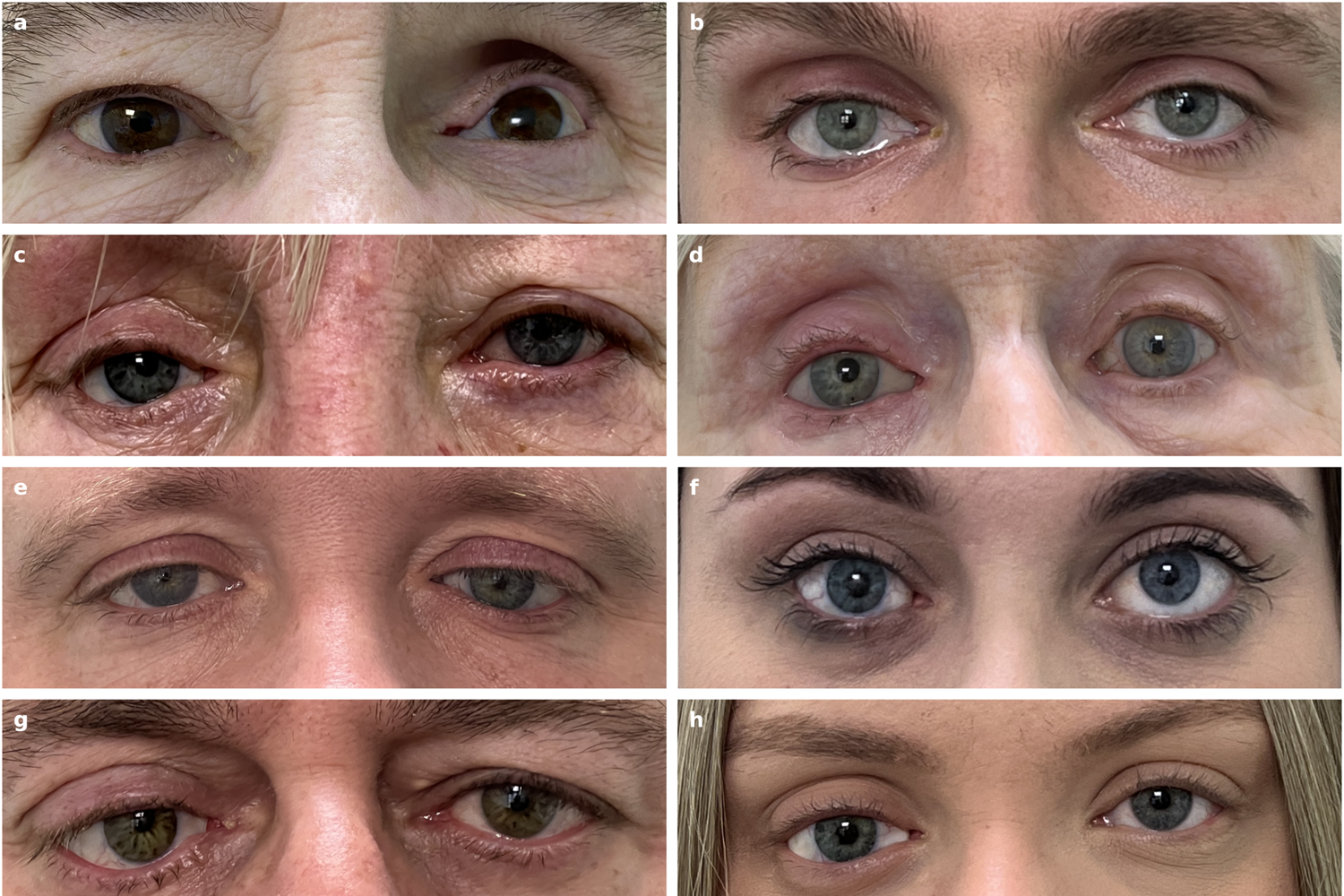

They scanned 10 patients’ eye sockets and healthy eyes, and the prosthetic was automatically shaped to fit the eye socket.

It only takes about 90 minutes to print a single prosthesis made of multiple materials in full colour, or about 20 hours to print 100 prostheses simultaneously.

The researchers were able to closely replicate the colour and anatomy of the other eye, in particular the colour, size, and structure of the iris, and appearance of the white outer layer of the eyeball.

Although the artificial eye needed some final adjustments, the researchers estimate that this approach required five times less labour compared to traditional processes and had more reproducible results.

Writing in Nature Communications, they add: “We envision that our findings motivate the research and development of data-driven design tools and multi-material 3D printing for other prosthesis types such as dental restorations or facial prostheses.

“It could even be possible to couple this development with more traditional prostheses and for example produce covers for prostheses that accurately match the patients’ appearance.”

Bookmark popover

Removed from bookmarks