Scientists create ultra-light, super strong new material based on wood and bone

Technique mimics the natural creation of ‘desert roses’ in some hot, arid areas of Africa

A new way of making lightweight and incredibly strong materials that have a similar structure to wood and bone has been developed by scientists in what they described as a “ground-breaking advance”.

They used a method of 3D printing to create a fog of tiny droplets of silver to build up the structures – again taking inspiration from nature.

The process is comparable to a rare event found in some African deserts where fog containing sulphur evaporates to slowly form crystalline “desert roses”.

One of the researchers, Professor Rahul Panat, of Washington State University, said: “This is a ground-breaking advance in the 3D architecturing of materials at nano- to macroscales with applications in batteries, lightweight ultra-strong materials, catalytic converters, super-capacitors and biological scaffolds.

“This technique can fill a lot of critical gaps for the realisation of these technologies.”

They have already filed for a patent on the technique, which they described in a paper in the journal Science Advances.

Silver was used in the study because it is an easy material to work with, but Professor Panat said any material that can be turned into nanoparticles could be shaped in the same way.

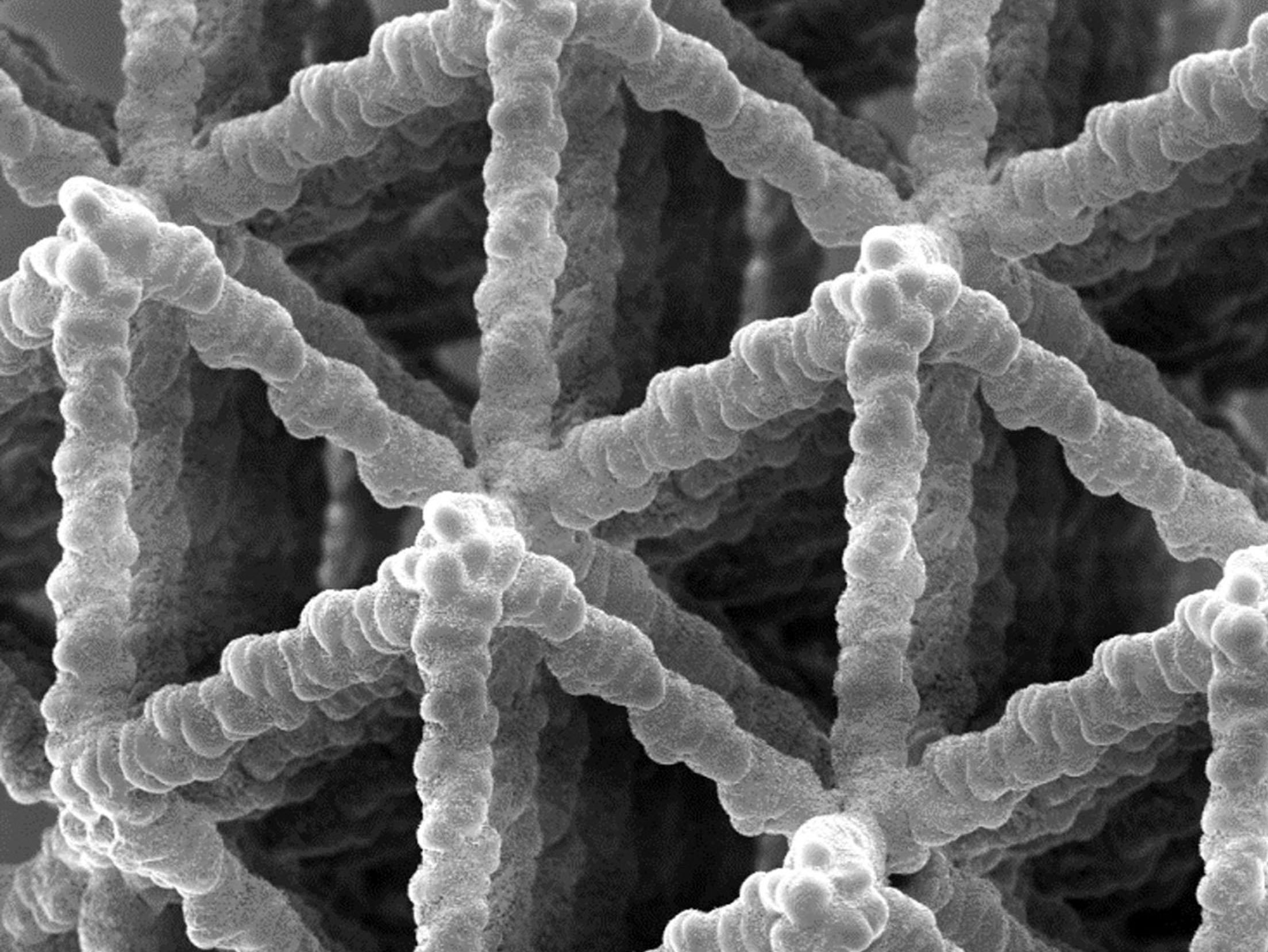

The resulting structures have a very large surface area, are porous and very strong.

They can be designed to form tiny bridges, spirals and electronic connections that look like accordion bellows or doughnut-shaped pillars.

The utilisation of 3D printing means the material can be produced with little waste, quickly and on a large scale, it is believed.

It could be particularly useful in batteries, the researchers said.

They are currently developing porous anodes and cathodes for batteries to replace the solid ones that are currently used.

This could increase the capacity and speed of the battery and allow the use of new and higher energy materials.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments

Bookmark popover

Removed from bookmarks