Scientists develop 1.4mm thick bomb-proof bag to protect against explosives on planes

The bag can be used to contain passenger luggage and is designed to withstand temperatures of 3,000C and a blast shockwave at a speed of 20,000 mph

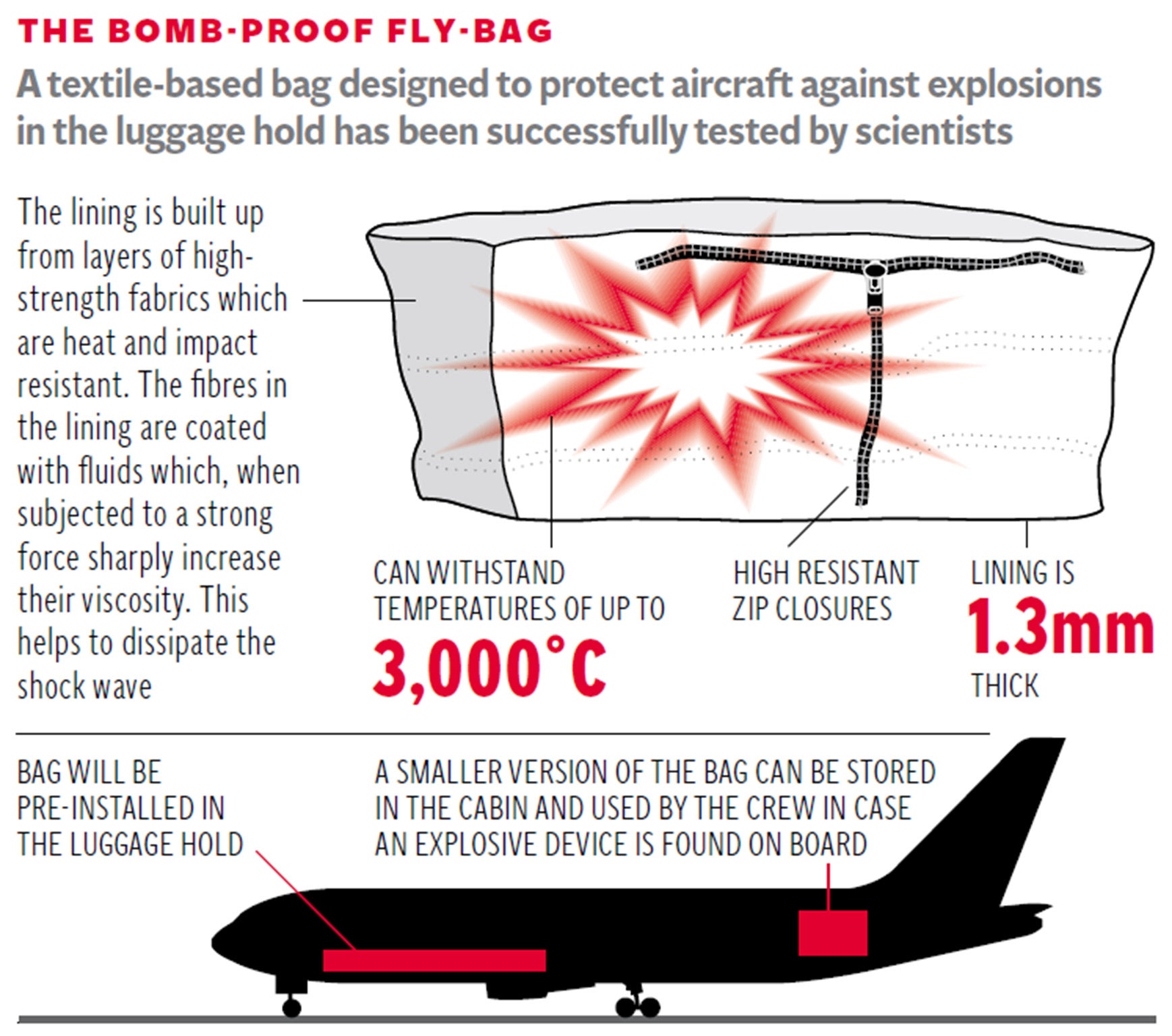

British scientists have helped invent a bomb proof bag just 1.4mm thick which can contain an explosion, in a bid to protect air passengers from the threat of explosives on board planes.

The material has already passed tests in a blast laboratory at Sheffield University, and on 28 July it emerged that trials on actual planes, at Cotswold Airport in Gloucestershire, have been successful.

The ultra-thin lining has been several years in development as part of a EU funded ‘Fly-Bag’ programme involving seven countries, in a bid to prevent a repeat of the Lockerbie bombing in 1988 in which 270 people died.

It can be used to contain passenger luggage and is designed to withstand temperatures of 3,000C and a blast shockwave at a speed of 20,000 mph, as well as containing shrapnel from an explosion.

Several explosions were set off in luggage inside the bomb proof bags in the holds of two disused passenger jets last week – with no major damage caused. Scientists then removed the bomb proof material and set off explosions to show what would happen – with the Boeing 747 and Airbus A321 left with huge gaping holes in their sides.

Commenting on the protection provided by the bomb bags during the latest tests, Dr Andy Tyas, from Sheffield University’s department of civil and structural engineering, said: “We placed sensors around the hold of the aircraft during testing to determine what damage had been caused to the aircraft during the explosions...preliminary indications show that there was no major damage.”

Dr Tyas, one of the lead researchers on the Fly-Bag project, described the results as “extremely promising” and added: “Key to the concept is that the lining is flexible and this adds to its resilience when containing the explosive force and any fragments produced. This helps to ensure that the Fly-Bag acts as a membrane rather than as a rigid-walled container which might shatter on impact.”

The fabric is impregnated with ‘Shear Thickening Fluids’ that strengthen in response to sudden force, and has four layers of material, including Aramid - which is used in body armour. And the bag is also coated with an elastomer - to enable it to stretch and withstand the extreme pressure of a bomb blast without breaking.

The British Airline Pilots Association (Balpa) welcomed the news of the technological advance.

In a statement, a spokesperson said: “Pilots strongly support research into how to make flights as safe as possible, and combat threats whenever they arise. We hope the aviation industry looks at the potential in this emerging technology and how to make the most of it in the interests of the safety of our passengers.”

The technology is an alternative to existing reinforced containers for luggage which are viewed as too heavy and expensive by many airlines, and is just months away from being commercially available, claimed a spokesperson for the Fly-Bag project, based in Genoa, Italy.

“It will probably be on the market after the end of the research project i.e. after September 2015,” they told The Independent. Meetings with potential customers are being planned, with airlines from Europe and the US having shown an interest, the spokesperson added.

But Professor Anthony Glees, director of the centre for security and intelligence studies at the University of Buckingham, commented: “To the best of my knowledge containing even a small explosive blast at 37000 feet would require technology that doesn't really exist.” He added: “Until and unless a real advance is made in a material which can protect people from explosive blasts, we need to carry on with the kind of security screening we have now.”

And Brandon Friend, executive director of the Airforwarders Association, a US-based air freight trade body, said: “While we applaud continuing research efforts focusing on explosive containment, dangerous items should be detected and avoided on the ground through a rigorous physical screening process combined with passenger and shipper advanced data targeting before the aircraft departs.”

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments

Bookmark popover

Removed from bookmarks