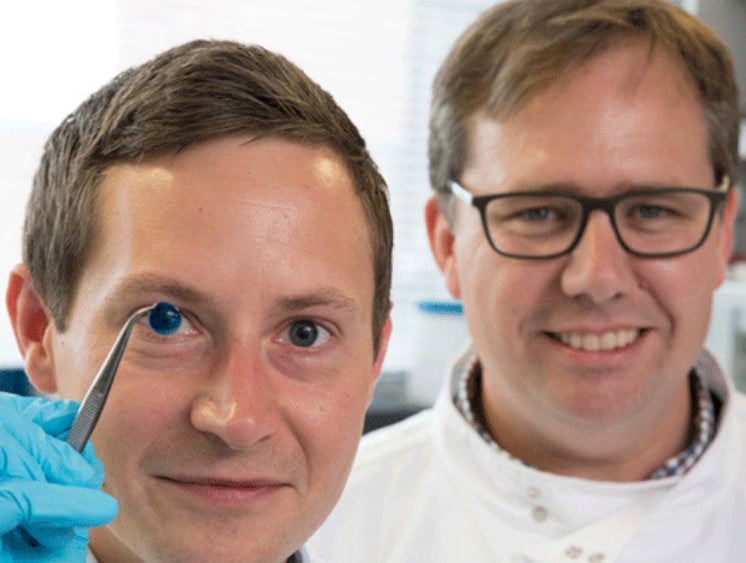

Scientists 3D print human cornea for first time, a technique which could save millions from blindness

Technique could eventually supply unlimited number of artificial corneas

A human cornea has been produced with a 3D printer for the first time - a development which is thought could eventually help millions of people around the world suffering from corneal blindness.

Pioneered by researchers at Newcastle University, it is thought the technique could supply an unlimited number of corneas - the transparent outer lens of the eye, that light passes through before hitting the retina at the back. Damage to it can distort vision or even lead to blindness.

Combining human stem cells from a healthy donor with collagen and alginate - a chemical often used to produce artificial limbs - the proof-of-concept research was able to produce a “bio-ink” for a 3D bio-printer.

It was then able print off a model of a cornea using the gel - building it by squeezing out the ink in concentric circles – in less than 10 minutes.

Stem cells were then added and left to grow to create a cornea which is theoretically ready for transplantation.

Up to 10 million people worldwide require surgery to prevent corneal blindness as a result of diseases, while another 5 million suffer total blindness due to corneal scarring.

“Many teams across the world have been chasing the ideal bio-ink to make this process feasible," said Che Connon, professor of tissue engineering at Newcastle University, who led the study.

“Our unique gel - a combination of alginate and collagen - keeps the stem cells alive whilst producing a material which is stiff enough to hold its shape but soft enough to be squeezed out the nozzle of a 3D printer.

“This builds upon our previous work in which we kept cells alive for weeks at room temperature within a similar hydrogel. Now we have a ready to use bio-ink containing stem cells allowing users to start printing tissues without having to worry about growing the cells separately.”

The team, who published their findings in journal Experimental Eye Research, also showed they were able to build a cornea to match a patient’s unique requirements. By scanning a volunteer’s eye, they were able to use the data to print off one with exactly the same dimensions.

Professor Connon said: “Our 3D printed corneas will now have to undergo further testing and it will be several years before we could be in the position where we are using them for transplants.

“However, what we have shown is that it is feasible to print corneas using coordinates taken from a patient eye and that this approach has potential to combat the world-wide shortage.”

Best Universities for Life Sciences and Medicine

Show all 20Dr Neil Ebenezer, director of research, policy and innovation at Fight for Sight, a British charity dedicated to pioneering eye research to prevent sight loss, said: “We are delighted at the success of researchers at Newcastle University in developing 3D printing of corneas using human tissue.

“This research highlights the significant progress that has been made in this area and this study is important in bringing us one step closer to reducing the need for donor corneas, which would positively impact some patients living with sight loss.

“However, it is important to note that this is still years away from potentially being available to patients and it is still vitally important that people continue to donate corneal tissue for transplant as there is a shortage within the UK. A corneal transplant can give someone back the gift of sight.”

Subscribe to Independent Premium to bookmark this article

Want to bookmark your favourite articles and stories to read or reference later? Start your Independent Premium subscription today.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies